A What-if Analysis consists of structured brainstorming to determine what can go wrong in a given scenario; then judge the likelihood and consequences that things will go wrong. What-if Analysis can be applied at virtually any point in the laboratory evaluation process.

- What is Hazard Analysis OSHA?

- How do you perform a PHA?

- Why is process hazard analysis important?

- What is Hazard Analysis Slideshare?

- What is the difference between Jha and JSA?

- What are process related hazards?

- What is a hazard analysis and risk assessment and why is it important?

- What is a hazard analysis and risk assessment?

- What must a process hazard analysis address?

- What is a PHA in construction?

- What is the difference between PHA and Hazop?

- How many steps are there in the PHA procedure?

- What are the roles and responsibilities of the process hazard analysis PHA facilitator?

- What are hazards PDF?

- What is a hazard Slideshare?

- What are types of hazards?

- What is the OSHA standard for PSM?

- What is a process safety hazard?

- What is covered by PSM?

- Is a JHA a risk assessment?

- Are Jha required by OSHA?

- What is STA in safety?

- What does Jha stand for?

- What do hazard assessments identify?

- What are the four main steps for hazard assessment and management?

- Why did OSHA create PSM?

- Who needs PSM?

- What are PSM regulations?

- Can PSM be done digitally?

What is Hazard Analysis OSHA?

A hazard is the potential for harm. … A job hazard analysis is a technique that focuses on job tasks as a way to identify hazards before they occur. It focuses on the relationship between the worker, the task, the tools, and the work environment.

How do you perform a PHA?

- DEVELOP A SCHEDULE FOR CONDUCTING THE PHA CONTAINING: Recommendations: …

- CHOOSE AN APPROPRIATE METHODOLOGY. …

- ESTABLISH THE PURPOSE, OBJECTIVES, AND SCOPE. …

- SELECT THE STUDY TEAM. …

- COLLECT REFERENCE INFORMATION. …

- DEVELOP WHAT-IF SUBSYSTEMS AND QUESTIONS. …

- ARRANGE THE TEAM MEETINGS. …

- CONDUCT A PHA STUDY.

Why is process hazard analysis important?

The process helps organizations identify a range of risks from equipment failures to human factors to improving safety, preventing downtime and protecting the surrounding environment.6) Hazard and Operability Study (HAZOP) A structured and systematic method that identifies equipment that is being used in a way that it was not designed to be, and which might create hazards and operational problems.

What is the difference between Jha and JSA?

A job safety analysis (JSA) is a safety management technique that focuses on and is used to identify and control the hazards associated with a job or task. … A job hazard analysis (JHA) is the term used by OH&S for “a technique that focuses on job tasks as a way to identify hazards before they occur.

Table 3-4, “Potential Process-Related Hazards,” contains a list of potential hazards that are associated with specific finished fishery products, as a result of the finished product form, the package type, and the method of distribution and storage. These hazards are referred to as process-related hazards.

What is a hazard analysis and risk assessment and why is it important?

Based on the item description, a hazard analysis and risk assessment (HARA) is conducted; this critical step serves to identify the hazards and malfunctions that can occur for the item under development and to categorize these hazards.What is a hazard analysis and risk assessment?

Risk assessment is a term used to describe the overall process or method where you: Identify hazards and risk factors that have the potential to cause harm (hazard identification). Analyze and evaluate the risk associated with that hazard (risk analysis, and risk evaluation).

What is the purpose of a PSM?The term Process Safety Management (PSM) became prominent because of an OSHA regulation that requires businesses to properly manage hazardous chemicals, with the goal of creating safe workplaces and preventing “unexpected releases of toxic, reactive, or flammable liquids and gases” that can cause disasters.

Article first time published onWhat must a process hazard analysis address?

The process hazard analysis is a thorough, orderly, systematic approach for identifying, evaluating, and controlling the hazards of processes involving highly hazardous chemicals. The employer must perform an initial process hazard analysis (hazard evaluation) on all processes covered by this standard.

What is a PHA in construction?

In alignment with regulatory compliance and/or company-specific protocol, a Process Hazard Analysis (PHA) prior to start-up of all new capital design projects is required.

What is the difference between PHA and Hazop?

PHA is meant to be a generic term for a study of process hazards. This terms covers a multitude of methods including HAZOP, What-if, and Checklist. … A “HAZOP/LOPA” is a form of LOPA whose goal is to determine if a tolerable level of risk is achieved, considering all of the safeguards that are available.

How many steps are there in the PHA procedure?

There are three basic steps to conducting the PHA study that the team will be required to perform during the review.

What are the roles and responsibilities of the process hazard analysis PHA facilitator?

JOB DESCRIPTION The Process Hazard Analysis/PHA Facilitator will plan, facilitate, and manage the PHA program for all US operating sites. The PHA is a cornerstone of our overall process safety program and include planning, execution, and reporting with key stakeholders across the organization.

What are hazards PDF?

A hazard is any source of potential damage, harm or adverse health effect on something or someone. Basically, a hazard is something that can cause harm or adverse effects such as to individuals as health effects, to the environment or to organizations as property or equipment damage.

HAZARD.. SOMETHING THAT HAS THE POTENTIAL TO CAUSE HARM TO PEOPLE, PROPERTY OR THE ENVIRONMENT OR, ANYTHING THAT HAS THE POTENTIAL TO CAUSE HARM , ILL HEALTH AND INJURY, DAMAGE TO PROPERTY PRODUCT OR THE ENVIRONMENT PRODUCTION LOSSES OR INCREASE CH MURLIDHAR.

What are types of hazards?

- Biological. Biological hazards include viruses, bacteria, insects, animals, etc., that can cause adverse health impacts. …

- Chemical. Chemical hazards are hazardous substances that can cause harm. …

- Physical. …

- Safety. …

- Ergonomic. …

- Psychosocial.

What is the OSHA standard for PSM?

As a result, OSHA developed the Process Safety Management (PSM) standard (issued in 1992), which covers the manufacturing of explosives and processes involving threshold quantities of flammable liquids and flammable gasses (10,000 lbs), as well as 137 listed highly hazardous chemicals.

What is a process safety hazard?

2. Process Safety Hazards: Hazards associated with the loss of primary containment of a hazardous substance. Process Hazards include fire, explosion, and toxic release. These hazards are associated with incidents which occur at low frequencies, but can have catastrophic consequences.

What is covered by PSM?

The purpose and application of the PSM standard is to prevent and mitigate catastrophic releases of HHC, which include fire/explosion hazards, toxic hazards, reactive hazards, and explosive hazards. As stated in Response 1, utility systems, including electrical utility systems can be part of a covered process.

Is a JHA a risk assessment?

Risk assessments are often confused with a Job Safety Analysis (JSA) or Job Hazard Analysis (JHA). The key difference between a risk assessment and a JSA is scope. Risk assessments assess safety hazards across the entire workplace and are oftentimes accompanied with a risk matrix to prioritize hazards and controls.

Are Jha required by OSHA?

There is no specific OSHA requirement for completing a JHA; however, OSHA does provides guidelines in 1910 Subpart I App B – Non-mandatory Compliance Guidelines for Hazard Assessment and Personal Protective Equipment Selection. … Using the JHA is an easy way to identify and control those hazards.

What is STA in safety?

Safety Task Assessments, or STAs, are performed before every work shift or meeting. An STA is a review of possible safety hazards, including incidents that might have occurred earlier in the day.

What does Jha stand for?

A Job Hazard Analysis (JHA) is an analysis of the hazards and risk associated which focus on identifying and controlling hazards.

What do hazard assessments identify?

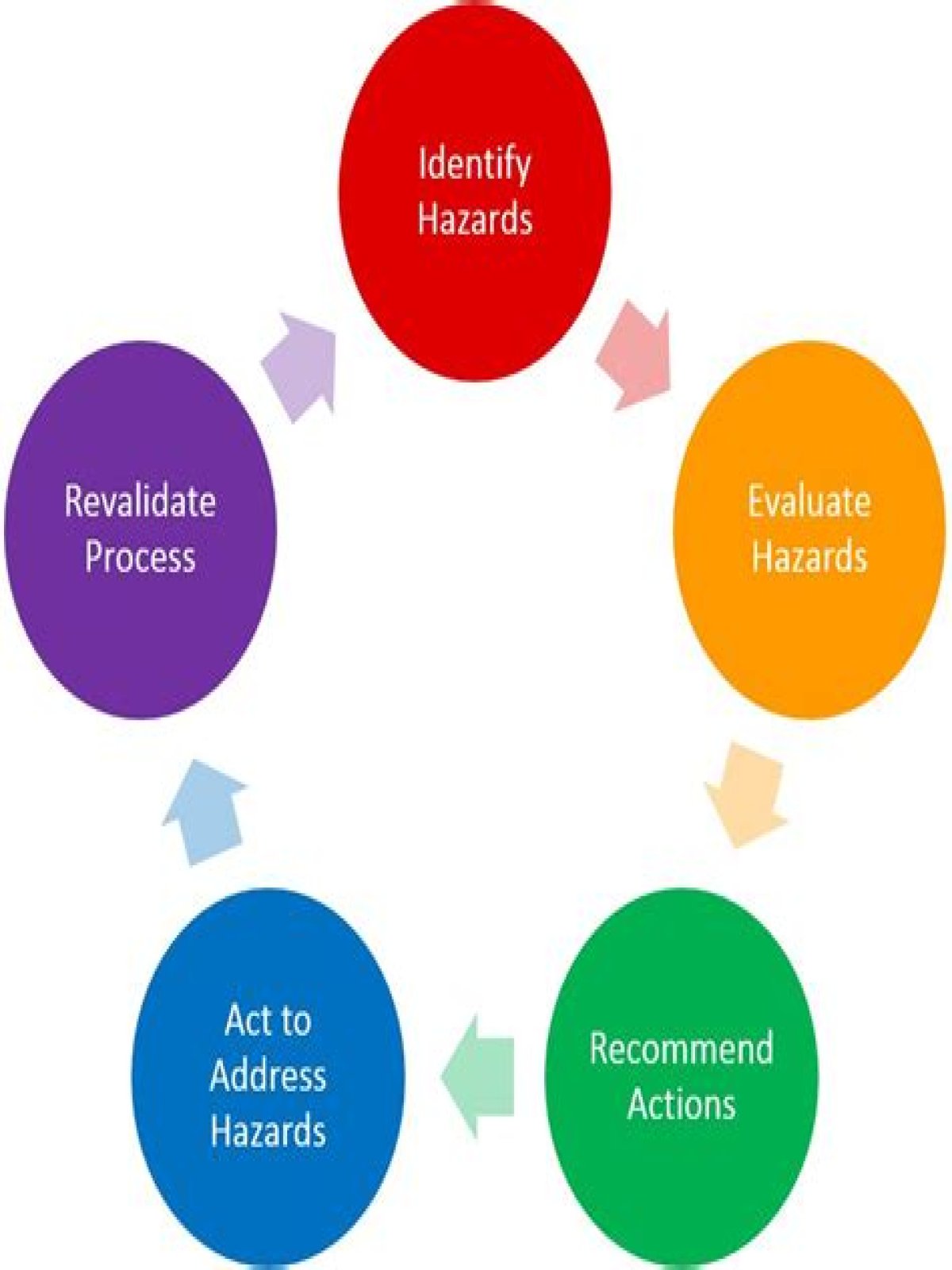

Hazard assessments are simply a process of identifying hazards, evaluating the risks presented by those hazards, and managing the risks of the hazards of the experiment to be performed by incorporating appropriate hazard controls into the experimental design process.

What are the four main steps for hazard assessment and management?

There are four steps to risk assessment: hazard identification, ex- posure assessment, dose-response as- sessment, and risk characterization.

Why did OSHA create PSM?

Why Did OSHA Develop PSM? In 1991, to help ensure safe and healthy workplaces, OSHA issued the Process Safety Management of Highly Hazardous Chemicals standard (29 CFR 1910.119). … OSHA developed PSM due to past industrial disasters resulting in deaths and environmental damages, including: Bhopal, India gas leak in 1984.

Who needs PSM?

OSHA PSM requirements apply to companies that deal with more than 130 specific reactive and toxic chemicals in listed quantities, as well as flammable gases and liquids in quantities of 10,000 pounds or more.

What are PSM regulations?

Process Safety Management (PSM) is a regulation issued by the U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA). … Industries handling hazardous chemicals are required to develop an effective PSM program that protects employees, contractors, and visitors of the facility.

Can PSM be done digitally?

Mandated training, PSM audits and PHAs have historically involved site visits, but some of these activities can now be conducted remotely with a digital PSM program. … Digital PSM software allows for audits, analyses and training to take place with little or no face-to-face contactin accordance with CDC guidelines.